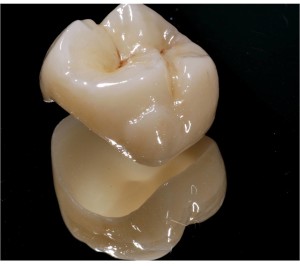

Emax cad porcelain now being used with Cerec

Are Sugar Free Sodas Bad For Your Teeth

December 14, 2015Dental Clinical Microscope

March 28, 2016Emax cad porcelain

Emax cad porcelain is a new materiel being used to make dental crowns. It has numerous advantages over standard porcelain. The Cad in Emax cad porcelain stands for computer aided design , being used by the CEREC SYSTEM that allows for the manufacture of a CEREC crown in the dental office in an hour.

Emax cad porcelain is a material called lithium disilicate. It is exceptionally natural in its appearance and is hard to differentiate from natural teeth. But the greatness of this porcelain material is not in its beautiful esthetics, but rather in its strength.

Porcelain strength

In general, dental porcelain is a strong materiel. It has great strength under compression. Imagine putting a piece of glass on a perfectly flat surface with 1 drop of water under it. Drive a car over it and it won’t break but put one grain of sand under and it will. It has poor resistance to lateral forces or flexural strength. Porcelain strength is measured in MPaS or megapascals. Regular porcelain has something like 150 MPa’s but Emax cad porcelain is in the order of 400MPA’s. More than 2 times as strong as a regular porcelain crown with esthetic advantages.

When we make a CEREC Emax cad porcelain crown, it comes in a block that is not fully formed and once the crown is manufactured, it needs to be fired in a porcelain oven to be completed and brought to strength. It is quite fascinating as the materiel has a blue color until it is removed from the oven when it takes it’s final beautiful shape and hue.

until it is removed from the oven when it takes it’s final beautiful shape and hue.

Depending on the situation, we use this material for many of our crown solutions.The translucency,opalescence, and light diffusion properties of IPS e.max lithium disilicate were all designed to copy natural tooth for beauty and quality restorations.