Peri implantitis and implant complications

July 21, 2015Implant esthetics

September 4, 2015Cerec Blocks

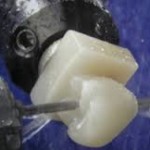

The cerec technology allows us to take a monolithic block of porcelain and create an exact a perfectly fitting restoration. The entire thing takes only about an hour from start to  finish. The Cerec Blocks of porcelain that we use and place into the machine to be ground down into crowns come in several types of materiel.

finish. The Cerec Blocks of porcelain that we use and place into the machine to be ground down into crowns come in several types of materiel.

Types Of Cerec Blocks

Feldspathic Porcelain

Cerec Blocks fall into 3 main categories and each has it’s own uses. The original blocks were standard dental porcelain. These blocks have been around for many years. The are strong, very wear resistant and very esthetically pleasing. The advantage of this porcelain is that it has expansion and contraction characteristics similar to tooth making it  comfortable with very few post op sensitivities. It can be stained and glazed to individualize each crown. The disadvantage is strength measure in mega pascals. These Cerec Blocks are among the weakest and can fracture if under extreme stress. Usually though they are fine and I have found them fracture only under very unusual circumstances and even then only on second molars.

comfortable with very few post op sensitivities. It can be stained and glazed to individualize each crown. The disadvantage is strength measure in mega pascals. These Cerec Blocks are among the weakest and can fracture if under extreme stress. Usually though they are fine and I have found them fracture only under very unusual circumstances and even then only on second molars.

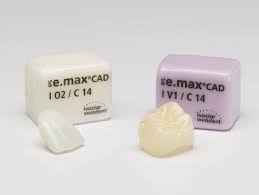

E-max

Next is E-max or lithium disilicate blocks. These blocks are the strongest options around,  they are very esthetic and have the smallest chance of fracturing. In fact it is quite rare that that ever happens. The only downside is that these Cerec Blocks must be fired in an oven in order to make them have their final strength. That means they need an extra 1/2 hour of time in order to finish the procedure.

they are very esthetic and have the smallest chance of fracturing. In fact it is quite rare that that ever happens. The only downside is that these Cerec Blocks must be fired in an oven in order to make them have their final strength. That means they need an extra 1/2 hour of time in order to finish the procedure.

Hybrid

Finally there are hybrid blocks which are made up of composite material with porcelain components. The advantages of these blocks is that have a certain microscopic flexibility making them useful in high stress situations.

No matter which if these Cerec Blocks we use, today we have a wide range of different options allowing us to give our patients one visit crowns in an hour that are esthetic, strong and comfortable